By Paula Lorenz and Dr. Ashley Holding

We often receive e-mails from companies who want to pitch us products made from novel ‘sustainable’ materials. One common theme is that they claim to offer something that is so sustainable, that it could be considered revolutionary – products that are supposedly capable of saving the planet from plastic waste.

The most common type of product we are contacted about are ‘sustainable’ alternatives to traditional plastic bags. Many of these are made from PVA, a material that is pivoted as an ideal alternative to plastic, as it supposedly is bio-degradable, water-soluble and generally an ‘environmentally-friendly’ solution to single-use plastics. But what really makes something a sustainable alternative?

We have known about PVA for a while and there have been things abound the sales claims around this material that concern us – both from a sustainability and a circular economy perspective, as well as from a scientific point of view – which has prompted us to write this article and share our thoughts. So, the following article will investigate the claims surrounding PVA bags and explain why we believe they are not the golden solution they are being advertised as.

1. The Polybag Problem

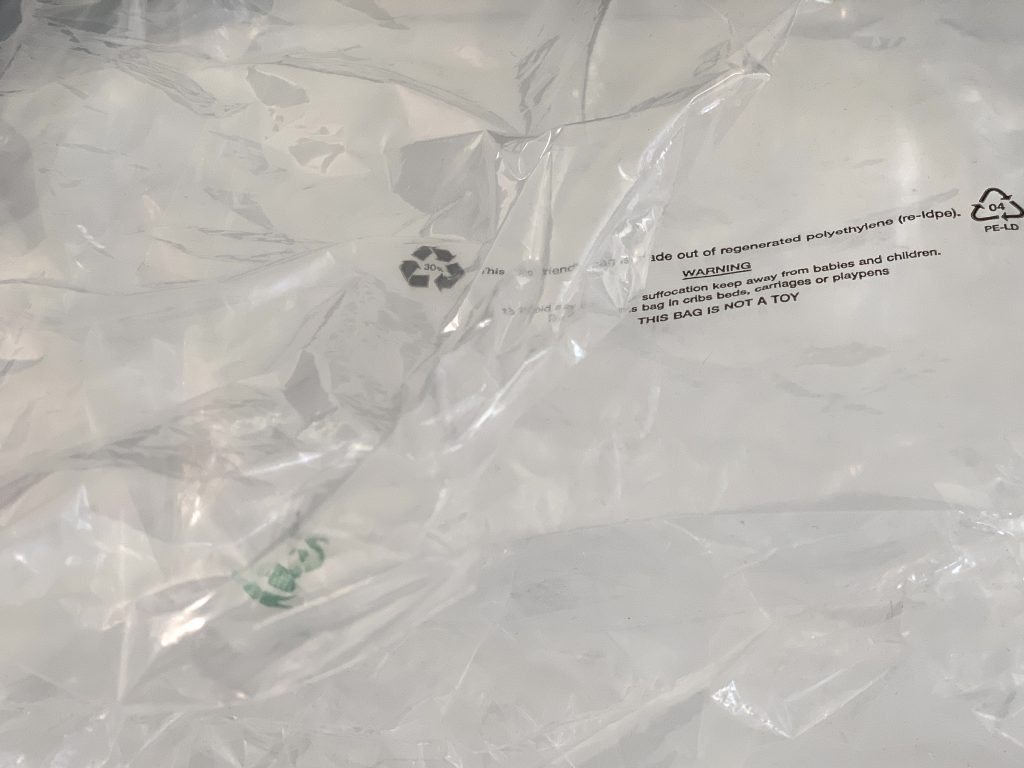

The term ‘polybag’ is typically used in the fashion and retail industry to refer to the clear plastic bags that come with almost any piece of clothing. Consumers would normally encounter them when ordering clothing online, leading to the common experience of being left with a mountain of plastic bags to dispose of. Many store items are also shipped in polybags, although the products get unwrapped before being presented in-store. The reason for this wide-spread use of polybags is that garments need to be protected on the long journey from the end of the production line to the customer or store. However, once the recipient has received the product, the plastic bag becomes redundant. The way this system works at present is very much ‘linear’: the plastic bags are single-use and disposed at their end-of-life, which is once they have fulfilled their purpose. This is why there have been a range of efforts to find more sustainable solutions to traditional polybags for quite some time.

Polybags are mostly made from Low Density Polyethylene, or ‘LDPE’, a plastic that has the ideal characteristics for its application: it is flexible, see-through, cheap, and it protects its contents well from moisture, dirt and damage. The problem in terms of sustainability is though, that although LDPE film packaging is technically recyclable it is not recycled in many places. Which means more often than not, it becomes waste that is either landfilled, incinerated, or in the most unfortunate of all circumstances, ends up somewhere in nature.

2. What is PVA?

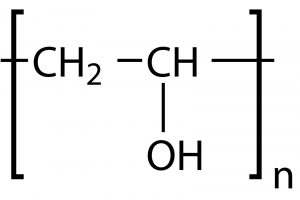

PVA (Polyvinyl Alcohol, sometimes known as PVOH) is a material that is made by polymerising vinyl acetate to polyvinyl acetate and then ‘hydrolysing’ the polymer with water to form the final product. This final hydrolysis step also enables certain properties to be tailored, such as strength, but also water solubility.

Contrary to some reports PVA is not bio-based: conventional fossil feedstocks, most commonly natural gas, are used. Ethane from natural gas is typically transformed into ethylene and then into the vinyl acetate building block.

When it comes to the solubility of PVA in water, the so called ‘degree of hydrolysis’ is one of the key factors: PVA that is only partially hydrolysed (i.e the polymer is only partially converted into polyvinyl alcohol) is more water soluble than fully hydrolysed PVA. The higher this ‘degree of hydrolysis’, the higher the temperature that is required to dissolve the material.

Subsequently, a higher degree of hydrolysis also means greater sturdiness. Therefore, a PVA bag that is sturdy enough to do its job well, is only soluble in water at higher temperatures. It is therefore very tricky to suggest that they might also be soluble in cold water, like for example in the ocean.

In contrast, another example is dishwasher tablets which have a water-soluble PVA wrapper: these wrappers easily dissolve in water, because the formulation of PVA used in them has a lower degree of hydrolysis. A bag on the other hand, cannot be as easily water soluble, because otherwise moisture and condensation would easily affect the structural integrity of the bag.

3. Are PVA Bags the Long-Desired Solution?

3.1 The Debate Around PVA and the Term ‘Plastic’

Some providers go so far as to suggest that PVA polybags are not made of plastic. For example, in an article about one such product, one provider claimed that their “products are not made out of actual plastic.”

So it is important to preface this debate by clarifying whether PVA is actually a plastic or not. To do this, the first simple step should be to consult a dictionary. How is the term ‘plastic’ commonly defined? The truth is, many definitions of ‘plastic’ can be found, with varying degrees of complexity, but the key elements are nearly always the following: it is formed of polymers (chains of many molecules) and is able to be moulded or shaped, typically in the presence of heat and/or pressure, and possibly contains additives.

In terms of a legal or regulatory definition, the EU attempted to come up with its own definition of what both a plastic and a single-use plastic is. The EU’s Single-Use Plastics Directive defines a plastic in the following way: “A material consisting of a polymer […], to which additives or other substances may have been added, and which can function as a main structural component of final products, with the exception of natural polymers that have not been chemically modified”.

Based on these criteria, it is evident that PVA is a plastic. PVA is a polymer that is capable of being moulded or shaped (in this case, into a thin film). By the EU definition, it is also the main structural component of the product and it is also not an unmodified natural polymer. PVA therefore fits both the typical linguistic usage of the term ‘plastic’ and the legislative use of the term.

The fact that some forms of PVA have the property of being water-soluble at specific temperatures, does not exclude it from being a plastic. Plastics can indeed have many different properties. For example, it is entirely possible to have a petroleum-based plastic that can easily biodegrade in home composting conditions. So whether a material is a plastic or not does not tell us anything about its biodegradability, solubility or generally about its environmental impact.

This discussion around plastic illustrates once again that one of the key selling points for novel materials is that brands want to cater to the increasing customer desire for ‘plastic-free’ or ‘sustainable’ products. As covered in many of our previous articles, this has lead to a range of opportunities for suppliers to sell materials to brands under the pretense of being sustainable or brands advertising products to consumers as more sustainable than they really are.

One interesting example for this is the British outdoor brand Finisterre. A major producer of PVA for plastic bag applications, whose material is known for being used to make water-soluble polybags used by Finisterre (amongst others), describes its PVA as a plastic. In the marketing copy for the Finisterre polybag, the brand highlights that it is “different to traditional plastics” while being careful to never explicitly state that the bag isn’t plastic. Their main claim however is that this new plastic bag is “eliminating the final piece of single-use, non-degradable plastic from our packaging”. This claim is questionable by most definitions though (including the EU’s Single-Use Plastic Directive), as this is still a single-use plastic product. It is used once, it is made from a plastic, and it is disposed of at the end of its life. Isn’t that the definition of a single-use plastic?

In fact, this is a key issue with the marketing of PVA-based hot water-soluble polybags: that they are suggested to be a solution to single-use plastics. This is certainly a bold claim which needs further scrutiny.

3.2 The Carbon Impact of PVA

Most sources that we analysed show that the carbon impact of PVA is much higher than that of Low-Density Polyethylene (LDPE), the material that polybags are traditionally made from.

For example, official life-cycle assessment (LCA) figures from a key supplier of a PVA material for water-soluble polybags, show that their ‘average’ formulation has a total global warming potential of 11.8 kg CO2 equivalents per kg.

The idemat database 2020, an open source academic LCA database, puts LDPE, the material used to make traditional polybags, at 1.87 kg CO2 eq per kg) and other sources also place it somewhere in this range.

If polybags made from both materials are roughly equivalent in weight, then that adds up to a very big difference in carbon footprint between the two materials: more than six times the carbon impact. In a recent report by the Sustainable Packaging Coalition and Fashion for Good, PVA was equally noted to be the most carbon-intensive (as well as water-intensive) polybag packaging option.

The same database as previously mentioned puts ‘generic’ PVA at 3.32 kg CO2 equivalents per kg, which may be based on the more common detergent pods grades, which is almost 1.8 times the carbon footprint of traditional LDPE. We don’t have enough information to conclude why the polybag PVA grades are so much more carbon intensive, but it may be related to the amount of extra energy required to fully hydrolyse PVA for their more resilient properties. This shows that how important full Life Cycle Assessments (LCAs) are in assessing new material options.

3.3 The Recyclability of PVA

Like nearly all thermoplastics, in theory PVA-based polybags are recyclable, because they can be melted and re-made into other objects.

However, like with all low-volume polymers, a recycling system is generally only feasible if there is enough of the material to make establishing a new recycling stream worthwhile. In theory, if there is a recycler willing to take PVA packaging film, and there were potential customers for the recycled output, then it could be recycled. This is the same story as with most bio-based plastics (as covered in other articles), where in theory, they could be recycled, but there is in general no infrastructure to do so.

PVA film is not currently separated out of household kerbside recycling waste anywhere in the world. So, if they were to be recycled, they would need to be collected by the retailer, for example by a mail-in scheme or drop-off box, and then shipped to the recycler. For such a low volume, light product, this is not likely feasible cost-wise or sustainability-wise: the transport emissions for such a scheme will likely make up a large fraction of the impact due to the low weight and volume of the PVA plastic film.

The same also applies in many places to LDPE film: in many countries, including the United Kingdom (in some regions) and in most of the United States plastic films in general are not collected and recycled from consumer kerbside waste. The technology to do so certainly exists, and some countries such as the Netherlands and Germany have a much more developed infrastructure to do so.

4. Biodegradability of PVA Bags

Some suppliers of PVA polybags also make claims around their biodegradability and compostability. Here we need to distinguish between a couple of things: firstly, there are specific claims that PVA-based polybags are compostable. How do these claims hold up, are PVA polybags compostable in a normal compost heap? Secondly, there are also claims surrounding the water degradability in the marine environment. Do PVA polybags easily break down in the ocean?

4.1 Compostability

Many suppliers of PVA-based polybags tend to suggest that the bags are compostable. However, their compostability depends on a few factors.

One manufacturer clarifies that their plastic films are only compostable up to a thickness of 15 μm or 20 μm in the case of the hot water-soluble grades. The tested grade of 27 μm thick film (more likely for these type of polybags) was just outside the window to be classed as compostable in accordance with the EN13432 standard. This means that only the thinnest of PVA films for polybags are able to be classed as ‘industrially compostable’ and they are not suitable for home compost heaps.

However, there are certainly many suppliers that claim their products do meet the EN13432 Standard, the key set of tests that are required for a product to be described as “industrially compostable” by most certification bodies. A problem is though that very few suppliers have any identifiable and traceable third party compostability certifications, such as a TÜV or DINCERTCO ‘HOME’ or ‘INDUSTRIAL’ COMPOSTABLE certifications and/or a European Bioplastics Seedling logo. So it is difficult to say with any confidence whether these claims can be taken at face value or not.

It is clear, that the PVA grades used in polybag production and the resulting polybags are just on the borderline of the criteria to be called at least “industrially compostable”. However, external proof for many suppliers is lacking. At least one supplier claims, however, to have met the criteria for home compostability for the lesser known Australian Bioplastics Association Home Compostability Standard, which measures if materials biodegrade at 20-30°C by 90%, within 180 days.

Furthermore, this brings us to the problem that regular readers of The Circular Laboratory may have spotted: even if they are able to be classed as industrially compostable, this only works in special facilities operating with specific conditions, where a separate waste collection and logistics infrastructure needs to be in place to get them there. In most cases, in many countries, compostable packaging will end up in the residual waste stream, destined for landfill or incineration.

Interestingly, although biodegradability is highlighted as one of the properties of the material it is not always the main focus of the advertising claims, with one supplier, for example, encouraging consumers to dissolve the material in hot water over composting it.

4.2 Marine Degradability

Another recurring theme in the marketing of these plastic bags is that they are said to be ‘marine-safe’. It is hard to define exactly what ‘marine-safe’ means, but a key element is surely the persistence of an item in the marine environment and the likelihood it will cause harm to marine life.

In the context of PVA bags, we need to evaluate then if they will actually dissolve or biodegrade in the ocean in realistic conditions, thus minimising harm to marine life.

As we have seen, PVA polybags are made in such a way that they only dissolve in hot water, since they need to be comparable to other plastic bags in terms of strength and stability. So a PVA plastic bag is unlikely to dissolve and disappear in the cold water conditions of the oceans. According to recent evidence it seems also unlikely that the plastic bag will biodegrade in the ocean due to the action of microorganisms. The study by the University of Vigo in Spain found that that PVA with a high degree of hydrolysis (corresponding to the hot-water soluble grades) is not marine degradable. The lack of degradability in the simulated marine conditions is especially stark when compared to PHB, a bio-based plastic that is known to be biodegradable in some marine conditions.

One of the main producers of PVA for water-soluble polybag applications, Aquapak, also addresses the topic of marine degradability in a white paper publicly available on their website.

In an earlier version of the whitepaper that was on the internet, released in March 2019, there is a clear conclusion by the authors of an attached report, written by the Open University, that there is no evidence for the plastics films’ marine degradability. In a later version of this whitepaper, released only a few months later, this specific paragraph was excised from the report, keeping everything else the same.

The removal of the paragraph (above, image) is the only change in the report by Open University from the older version to the newer version. It can be seen that the indentation from the old paragraph is preserved, with the sentences leading to an oddly hanging sentence at the end of the report. The deleted paragraph said:

“To summarise, based on the results of these experiments, it can be concluded that PVOH is not biodegradable under simulated compost and anaerobic environments over a time of <1 year. […] PVOH was not biodegradable in sea water (as measured by CO2 release) but showed some chemical changes in terrestrial soil environments after one year of exposure. The presence of PVOH in aquatic environments had no adverse impacts on key indicator species of algae and water flea. “

It’s not clear why this was removed from the report, but it does seem to suggest that the evidence surrounding marine degradability is not particularly clear. In general, there are no universally agreed international standards for marine degradability (even though some third-party certifications do exist, based on a couple of national standards) and work in this area is certainly ongoing. The only thing that is clear, from this report, and the scientific literature in general, is that PVA when dissolved in low enough concentrations in water is not particularly toxic. None of the suppliers we surveyed had any marine degradability certifications such as TÜV “OK Marine” Biodegradable – which would give more concrete proof as to their marine degradability.

We asked Dr. Ricardo Beiras, Professor at the University of Vigo and expert in marine pollution, and author of a recent study into the biodegradability of PVA plastics in marine conditions, if we could consider PVA-based polybags to be ‘marine-safe’, and he explained further:

“Concerning the PVA materials we recently tested, they are eco-toxicologically innocuous, but they don’t degrade at all in seawater. In fact, they are not even soluble in seawater in environmentally realistic conditions. Therefore, the scientific answer is quite straight forward: PVA polymers do not get dissolved and do not degrade in the marine environment in realistic natural conditions, and thus will not solve the problem of persistence and potential ingestion by marine organisms”.

“Therefore, the scientific answer is quite straight forward: PVA polymers do not get dissolved and do not degrade in the marine environment in realistic natural conditions, and thus will not solve the problem of persistence and potential ingestion by marine organisms”.

Dr. Ricardo Beiras, Professor at the University of Vigo

In short, there is no specific evidence that we have seen, either in the scientific literature or in manufacturer documentation, to suggest that ‘hot water soluble’ PVA-based polybags will biodegrade in seawater environments. However, the PVA itself, when already dissolved in hot water, is not particularly eco-toxic to marine life when mixed in dilute concentrations. This might be why the tagline ‘marine-safe’ is used. However, based on the evidence, there is certainly no reason as to why they should be treated any different to other forms of marine litter or litter in the environment in general.

5. End-of-Life Strategy of PVA: What is Left?

5.1 Disposing of PVA with Hot Water

In this scenario we need to consider the carbon impact of individually heating a kettle to dispose of a plastic bag. Especially considering the typical energy grid mix of most countries, this is a very inefficient end-of-life option. Dissolving an individual plastic bag at home, with a kettle of hot water, is not preferable from a carbon standpoint when compared to incineration, especially when the latter generates energy for the grid.

Back-of-the-envelope calculations suggest that with a 10 gram PVA polybag (based on the manufacturer figures above, and taking into account a typical extrusion process – data: idemat 2022, excluding shipping and printing) the end-of-life contribution of heating a kettle of water would be more than 30 times that of the bag itself and over 97% contribution to the total cradle-to-grave footprint, based on the current UK grid carbon intensity (at the time of writing) and heating 250 ml of water in an 80% efficient electric kettle. With an excess use of water, such as boiling a full kettle, or dissolving PVA in much larger amounts of water, the carbon footprint would be much greater.

5.2 What Happens When PVA Goes Down The Drain?

There is certainly evidence that in wastewater treatment plants, the microorganisms in the plants acclimatise to the presence of PVA from laundry pods and eventually start to digest it, as well as bacteria found in the wastewater streams of certain paper plants that use certain grades of PVA in coatings. This does, to a degree, also depend on the specific type of water treatment in place for the region or country. However, the research to date focuses on the more highly soluble PVA grades used in detergent capsules and not the more resilient grades used in plastic bags. The effect of the ‘degree of hydrolysis’, as well as the length of the polymer molecules that define these formulations has not been well studied.

In fact, this review paper also puts it very plainly: “Not all PVOH (PVA) is equally water soluble, and neither is it equally biodegradable … several PVOH (PVA) applications outside of the detergents sector, with lower water solubility, may indeed exhibit a less favourable biodegradation profile”.

6. Summary

Based on our investigation, we believe PVA bags are not the holy grail solution to plastic waste they are being promoted as. Contrary to some manufacturers claims, PVA is not plastic-free because it is a plastic, and it is made from fossil resources. It is also not home-compostable and only industrially compostable within certain conditions. Moreover, its CO2 footprint is worse than that of traditional LDPE polybags.

But above all else, it is important to conclude that PVA polybags are not a sustainable solution to single-use plastics, as they are single-use plastics themselves and do not have a valid end-of-life strategy. In general, it is difficult to see how hot water-soluble polybags fit into the concept of a circular economy: most suggested end-of-life pathways involve the material being destroyed, either by dissolution in water, or industrial composting. This would necessitate production of new, virgin material to fill the gap in demand. And given the carbon impact of the material itself, a large-scale switch to PVA – even excluding the large carbon impact of disposing of such bags with hot water – would entail an increase in carbon emissions.

What brands and consumers can learn from this once again, is that it is important to not just take any sales claim at face value when it comes to supposedly sustainable products. To demonstrate this, here is an excerpt of how one supplier describes PVA: “PVA is truly the only plastic substitute to rid the world of plastic pollution once and for all. With PVA, there are no compost issues, no biodegradable [sic] issues, it simply dissolves in water, within minutes.”

In essence: all that glitters, is not gold.